Surface Mount Technology Latest News

Inaugurating VVDN Technologies’ SMT (Surface Mount Technology) Line at Manesar recently, the Minister of Electronics and Information Technology noted that electronics manufacturing in India has risen 5-fold in the last decade, topping Rs 11 lakh crore.

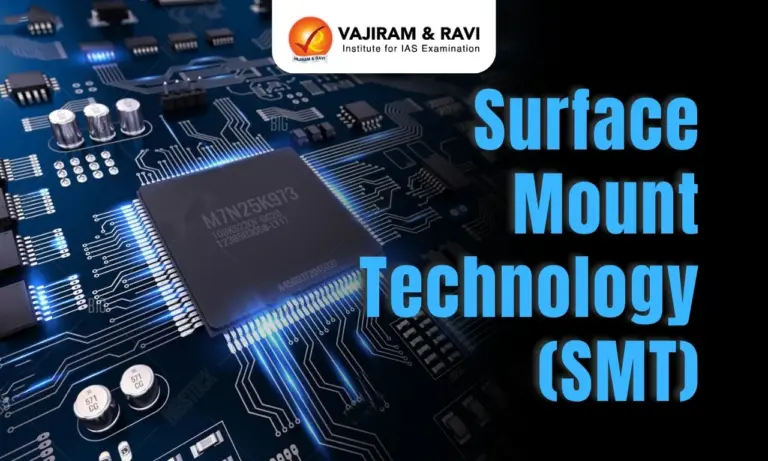

About Surface Mount Technology

- It refers to a manufacturing technique where electronic components are directly applied to the surface of a printed circuit board (PCB).

- SMT, developed in the 1960s and 1970s, replaced conventional through-hole technology (THT), producing more compact, economical, and efficient electronic devices.

- This method enables automated production to conduct a more extensive assembly, resulting in the creation of a fully functional circuit board.

- Any electronic element installed in this manner is identified as a surface-mounted component (SMD).

- In opposition to conventional manufacturing techniques, SMT removes the necessity for elements to be placed through apertures; rather, elements are attached to the board via the process of soldering.

- The two main soldering techniques are reflow soldering and wave soldering.

- Assembling PCBs using SMT involves various steps like solder paste application,component placement, reflow soldering, and cleaning.

- SMT is used in many industries like consumer electronics, medical, and aerospace industries.

- THT vs. SMT:

- As compared to THT, SMT has cheaper production costs, increased component density, and superior electrical performance. But the initial cost is high, and it is difficult to repair.

- The process for SMT production setup is faster when compared to THT. This is because components are mounted using solder paste instead of drilled holes. It saves time and labor-intensive work.

- SMT supports microelectronics by allowing more components to be placed closer together on the board. This leads to designs that are more lightweight and compact.

- Simplicity: In THT, lead wires pass through the holes to connect components. Because SMT components are soldered right onto the PCB, the overall makeup is far less complex.

- The heat dissipated in SMT is also less than through-hole components.

Source: ET

Last updated on March, 2026

→ UPSC Final Result 2025 is now out.

→ UPSC has released UPSC Toppers List 2025 with the Civil Services final result on its official website.

→ Anuj Agnihotri secured AIR 1 in the UPSC Civil Services Examination 2025.

→ UPSC Marksheet 2025 Will be out soon.

→ UPSC Notification 2026 & UPSC IFoS Notification 2026 is now out on the official website at upsconline.nic.in.

→ UPSC Calendar 2026 has been released.

→ Check out the latest UPSC Syllabus 2026 here.

→ UPSC Prelims 2026 will be conducted on 24th May, 2026 & UPSC Mains 2026 will be conducted on 21st August 2026.

→ The UPSC Selection Process is of 3 stages-Prelims, Mains and Interview.

→ Prepare effectively with Vajiram & Ravi’s UPSC Prelims Test Series 2026 featuring full-length mock tests, detailed solutions, and performance analysis.

→ Enroll in Vajiram & Ravi’s UPSC Mains Test Series 2026 for structured answer writing practice, expert evaluation, and exam-oriented feedback.

→ Join Vajiram & Ravi’s Best UPSC Mentorship Program for personalized guidance, strategy planning, and one-to-one support from experienced mentors.

→ Shakti Dubey secures AIR 1 in UPSC CSE Exam 2024.

→ Also check Best UPSC Coaching in India

Surface Mount Technology FAQs

Q1. What is surface mount technology?+

Q2. Which of the following is a main soldering technique used in surface mount technology?+

Q3. What is a key advantage of Surface Mount Technology (SMT) over through-hole technology (THT)?+

Tags: prelims pointers Surface Mount Technology Surface Mount Technology upsc upsc prelims current affairs