Cryogenic technology refers to the field in which materials such as liquefied gases can be stored, transported and used at ultra-low temperatures, generally less than -160 ℃. Cryogenics have numerous applications but the most significant amongst them is its use in space technology, to construct a rocket engine used to carry heavier payloads. The combination of liquid oxygen and liquid hydrogen provides a higher specific impulse due to more thrust per unit mass.

In 2014, India became a part of the elite list of countries which have indigenous cryogenic technology and its application in space when it successfully launched the GSLV-DF rocket. Today, ISRO uses the Launch Vehicle Mark-3 (LVM-3) rockets whose upper stage is cryogenic.

What is Cryogenics?

Cryogenics was invented in the nineteenth century by a group of scientists who experimented with liquefying gases at low temperatures, and first developed in the United States. The study of the production and behaviour of materials at extremely low temperatures (below -150 degrees Celsius) to lift and place heavier objects in space is known as cryogenics.

- Gases used in Cryogenics: Cryogenic liquids are liquids that have a normal boiling point below –130°F.

- They happen to be some of the most commonly used industrial gases that are handled, transported, and stored in the liquid state at cryogenic temperatures. These include nitrogen, hydrogen, oxygen, helium, and argon.

- Cryogenic Dewar: A cryogenic dewar is a vessel designed to store cryogenics (substances with lower boiling points than most others).

- To accomplish this, the dewar flasks create a vacuum space between the outside walls and the liquid stored inside, which acts as an insulator.

Applications of Cryogenic Technology

Cryogenic technology has many applications including:

- Medical and Pharmaceutical Industry: A "regular" cryogenic freezer can be used to freeze many substances, including certain drugs, blood cells, stem cells, and eggs.

- It can be used in cryosurgery which involves the use of extreme cold to destroy or remove abnormal tissues, such as tumours or warts.

- MRIsystems use cryogens (usually helium) to cool the magnet in the MR scanner.

- Food Industry: Cooling food, while it is at its best quality, is crucial within this industry.

- Cryogenic refrigeration systems have proven to be the most effective solution in this regard.

- Some other cryogenic applications include cooling trays containing liquid nitrogen Into which foods are immersed for super-fast cooling.

- Space: Cryogenic gases are used as fuel, and liquid helium is used to cool detectors in space, allowing them to take highly accurate measurements.

- The cryogenic test chamber prepares satellites and rockets for departure.

- Automotive industry: The cooling box is a common cryogenic application in the automotive industry. This method employs nitrogen-cooled cooling and shrinking to insert an automobile item into an engine block with minimal force.

- When the component reaches the required temperature, it expands and locks into position.

- Superconductors: By cooling magnets with cryogenic gases to almost absolute zero, superconductors can be made.

- Scientific Research:

- Cryogenic technology is used in Nuclear magnetic resonance (NMR) to determine the chemical structure of a molecule.

- They are also used for the cryopreservation of organs, tissues embryos, etc. to be used in research.

- Superconducting magnets have many applications in physical research such as in the particle accelerators and Large Hadron Collider, Tokamak, etc.

- Transportation of inflammable gas: Cryogenics is used to transport gases in cylinders such as LNG, LPG, etc.

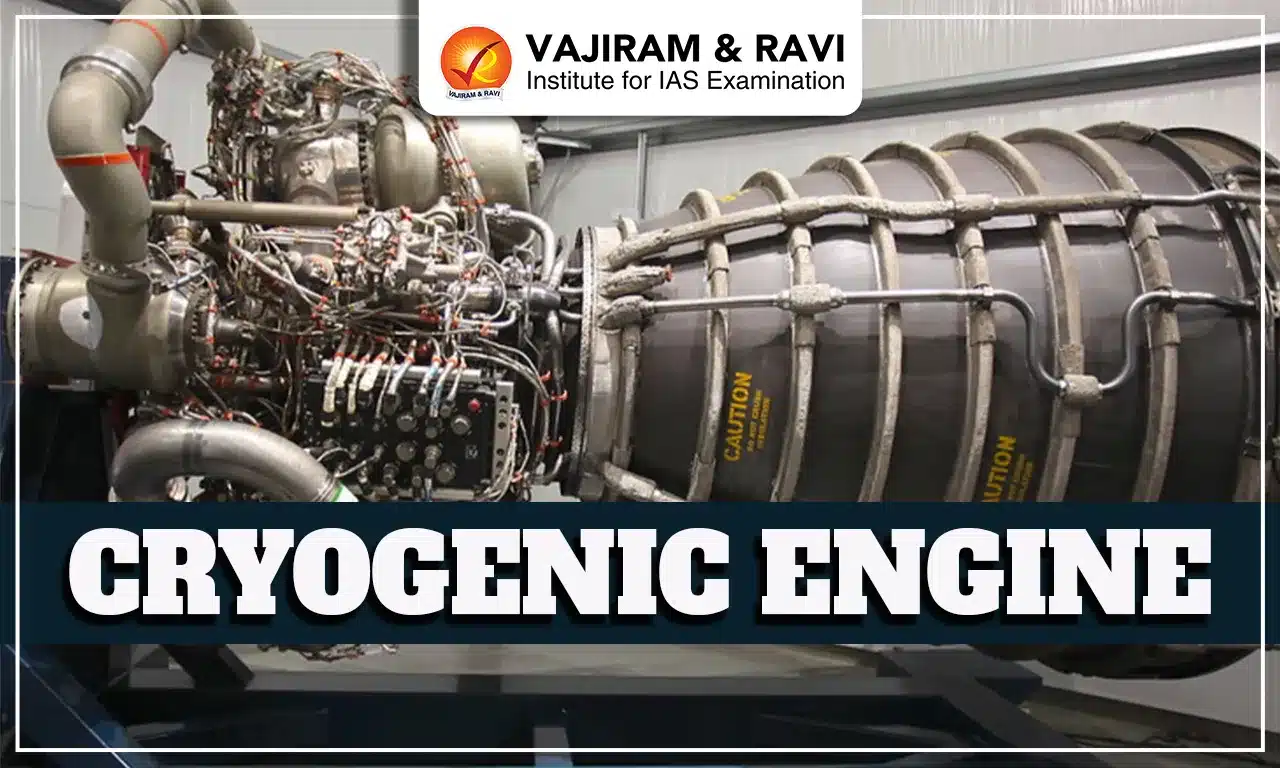

What is Cryogenics Engine?

A cryogenic engine, also known as a cryogenic stage, is the final stage of a space launch vehicle that uses cryogenics.

- Due to the use of propellants at extremely low temperatures, the cryogenic stage is a much more complex system than solid or liquid propellant (stored on Earth) stages.

- Working of Cryogenic Engine: The cryogenic engine makes use of Liquid Oxygen (LOX) and Liquid Hydrogen (LH2) as propellants which liquefy at -183 degrees C and -253 degrees C respectively.

- Components of Cryogenic Engine: Its major components are a combustion/thrust chamber, igniter, fuel injector, fuel cryo pumps, oxidizer cryo pumps, gas turbine, cryo valves, regulators, fuel tanks, and a rocket engine nozzle.

Advantages of Cryogenic Engine

- High Energy per unit mass: Because liquid propellants such as oxygen and hydrogen provide very high amounts of energy per unit mass, the amount of fuel carried aboard rockets is reduced.

- Carries Higher payload: Specific impulse (a measure of the efficiency) achievable with cryogenic propellants (liquid Hydrogen and liquid Oxygen) is much higher compared to earth-storable liquid and solid propellants, giving it a substantial payload advantage.

- Fuel density: More fuel can be stored in the tank due to the higher density of liquid fuel stored at low temperatures.

- Cooling: The engine can be cooled by using the fuel. As a result, additional cooling circuits are not required to keep the engine cool.

- Clean Fuels: Hydrogen and oxygen are clean fuels, they give out only water.

- Cryogenic engines are also non-toxic and non-corrosive in nature.

- Economical: The use of hydrogen as a fuel and oxygen as an oxidiser has also proved to be economical.

- When compared to other propellants, such as solid and liquid propellant rocket engines, a cryogenic engine produces more force per kilogram (higher thrust) of cryogenic propellant used, which makes it more economical.

Challenges related to Cryogenic Technology

Despite having significant applications across the sectors, cryogenics have some shortcomings as well, such as:

- Engineering challenges: Liquid hydrogen being a low-density fluid requires very high-speed multi-stage pumps to develop the required delivery pressures.

- The very high speed calls for meticulous design and fabrication of complex-shaped hardware within the stipulated tolerances.

- Complex Storage: In planned planetary explorations, liquid hydrogen, and liquid oxygen are used as fuel and oxidants.

- Such explorations necessitate the long-term storage of cryogens, as well as heat insulation technology to protect the heat from the outside.

- Hazards related to cryogens: The primary hazards of cryogenic liquids include both physical hazards such as fire, explosion, and pressure, but also health hazards such as chemical toxicity or severe frostbite and asphyxiation.

India and Cryogenic Technology

The Indian government gave formal approval to the Cryogenic Upper Stage (CUS) project in 1994. ISRO’s cryogenic team made the first 7.5-tonne engine in 2000. India is now one of only six countries, along with the United States, France (European Space Agency), Russia, China, and Japan, to have developed their own cryogenic engines. ISRO took on the task of creating cryogenic engines.

- First Test and Flight: In 2003, ISRO successfully tested its first cryogenic engine.

- The first successful flight occurred in 2014 when ISRO launched the GSLV-DF rocket.

- CE-20: For the Chandrayaan-3 mission, the CE-20 cryogenic engine was used. The CE-20 was India's first cryogenic engine with a gas-generator cycle, as well as ISRO's largest cryogenic engine.

- CE 20 is India's largest cryogenic engine and was developed by the Liquid Propulsion Systems Centre, ISRO.

- Semi-Cryogenic Engine: In 2023, ISRO conducted the first hot test on an intermediate configuration of the Semi-cryogenic Engine, known as the Power Head Test Article (PHTA).

- A semi-cryogenic engine uses refined kerosene instead of liquid hydrogen. The liquid oxygen is used as an oxidiser.

- The advantage of this is that refined kerosene is lighter than liquid fuel and can be stored at a normal temperature.

- Integrated cryogenic engine manufacturing facility (ICMF): The ICMF, established by Hindustan Aeronautics Limited (HAL) aims to produce cryogenic and semi-cryogenic engines needed for the Indian space programme.

- The ICMF brings together the manufacturing and assembly processes for these engines in one place.

Significance of Cryogenic Technology for India

India has become a fully independent member of the global space community, wherein it no longer has to depend on anyone to launch its heavier satellites into space. Cryogenic engines have significantly contributed in this direction.

- Increased payload: They offer a higher specific impulse, which measures the efficiency or thrust of an engine, resulting in an increased payload capacity.

- Manned space missions: It has also improved the prospects of ISRO upgrading its rockets to launch manned space missions, once GSLV is certified ‘Man Rated’, that is, fit to carry astronauts into space.

Last updated on January, 2026

→ Check out the latest UPSC Syllabus 2026 here.

→ Join Vajiram & Ravi’s Interview Guidance Programme for expert help to crack your final UPSC stage.

→ UPSC Mains Result 2025 is now out.

→ UPSC Notification 2026 Postponed for CSE & IFS which was scheduled to be released on 14 January 2026.

→ UPSC Calendar 2026 has been released.

→ UPSC Prelims 2026 will be conducted on 24th May, 2026 & UPSC Mains 2026 will be conducted on 21st August 2026.

→ The UPSC Selection Process is of 3 stages-Prelims, Mains and Interview.

→ Prepare effectively with Vajiram & Ravi’s UPSC Prelims Test Series 2026 featuring full-length mock tests, detailed solutions, and performance analysis.

→ Enroll in Vajiram & Ravi’s UPSC Mains Test Series 2026 for structured answer writing practice, expert evaluation, and exam-oriented feedback.

→ Join Vajiram & Ravi’s Best UPSC Mentorship Program for personalized guidance, strategy planning, and one-to-one support from experienced mentors.

→ UPSC Result 2024 is released with latest UPSC Marksheet 2024. Check Now!

→ UPSC Toppers List 2024 is released now. Shakti Dubey is UPSC AIR 1 2024 Topper.

→ Also check Best UPSC Coaching in India

Tags: cryogenic technology quest